Inside The Crumpet Factory!

We've had a long-standing desire to do a tour of a crumpet factory.

The sights! The smells! Meeting the tireless Trojans who keep our shelves full of holy delights!

Sadly, we seem to be thwarted at every turn.

WARBURTONS

(Through a friend of a friend) in 2021, we got a green light for a factory visit from Mr Jonathan Warburton himself. We could hardly contain our excitement!

Practical arrangements were passed on to Tearmh Taylor, Corporate and Consumer Affairs Manager. Sadly, our excitement was low priority for Teamrh, who was ultimately so busy and important that she couldn't find the time to respond to our emails. Not very Warburtons, but there we are.

LAKELAND BAKE

Separately, before the lunacy of lockdown, late in 2019 we received a message from Pete Turner, who founded and runs Lakeland Bake. Alongside their own range, Lakeland Bake produce own-brand crumpets for the likes of M&S, Aldi and Asda. They also undoubtedly lead the way in the "fun shapes" and "occasional" market.

Pete's exact message was "Fantastic!! Keep up the great work & if you are ever up in Carlisle I would be very happy to show you around my crumpet factory". Which is so Willy Wonka!

We were slow to take Pete up on his offer - the long and unpredictable era of lockdowns began shortly after his message - and it was two years before we eventually sprang into action.

Unfortunately, our emails since then seem to be ending up in spam - and we never feel confident that our telephone messages are getting through - so again we've hit a dead-end.

JONES' VILLAGE BAKERY

We also got in touch with the award-winning Jones' Village Bakery in Wrexham, famed for a visit from Harry and Meghan, before they disgraced themselves. Tracie Edwards, National Account Manager, was initially enthusiastic - and we had high hopes of a trip to North Wales. Sadly, Tracie ultimately did a Teamrh on us and stopped responding.

So, with heavy hearts, we concluded that the only way forward at this stage was a vicarious tour with BBC's "Inside The Factory", first aired in April 2023, and presented by loveable turnip, Greg Wallace.

So what did we learn?

The factory:

- is in Burnley

- is the largest of 11 Warburtons bakeries

- covers five acres and employs around 270 people

- produces an astonishing 432 million crumpets per year*

* We are a little sceptical about this as Warburtons produce around 700 million crumpets a year and we would have imagined that the load would have been shared more evenly across their facilities. We might have picked this up incorrectly, but cannot check as the episode is no longer available.

Unsurprisingly for production at this scale, it's a thoroughly automated operation: crumpet production takes less than two hours from start to finish!

The crumpet mixture comprises roughly equal parts of dry and liquid ingredients:

Dry: Flour*, baking powder, sugar, calcium propionate **

Liquid: Water, yeast, salt solution

* Warburtons use 13 varieties of wheat for their flour

** Calcium propionate is a preservative used in numerous foodstuffs

The ingredients are mixed together in giant blenders in the Mixing Room, where the baking powder reacts with the liquid to start the bubbling process.

The batter is transferred from there to Fermentation, where the yeast feeds on the sugar in the mixture to produce more CO2 and bubbles.

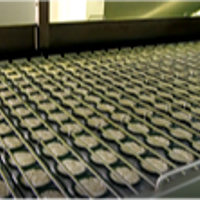

From there, the mixture is transported to the Crumpet Plant, where the batter is dropped into crumpet rings on hot plates, with a temperature of 175C. This heats the baking powder, expanding the crumpets, releasing steam and creating the flutes up to the surface of the crumpets.

The crumpets spend about 5 minutes on the hot plates, being lightly toasted for 22 seconds towards the end to add some colour to the top.

They then go through a cooling process before wending their way to packaging.

Shelf-life is obviously critical, so alongside the calcium propionate, the packs are pumped with carbon dioxide, giving mould no oxygen to work with.

Warburtons crumpets have a shelf-life of 8 days from when they leave the factory.

Quality control operates throughout the process. Any rejects become animal feed (or crumpet beer).

After all the high-tech wizardry, the crumpets are packed onto traditional bakers' trays, which is nice.